Services

- Detailed Quotes

- Value Engineering

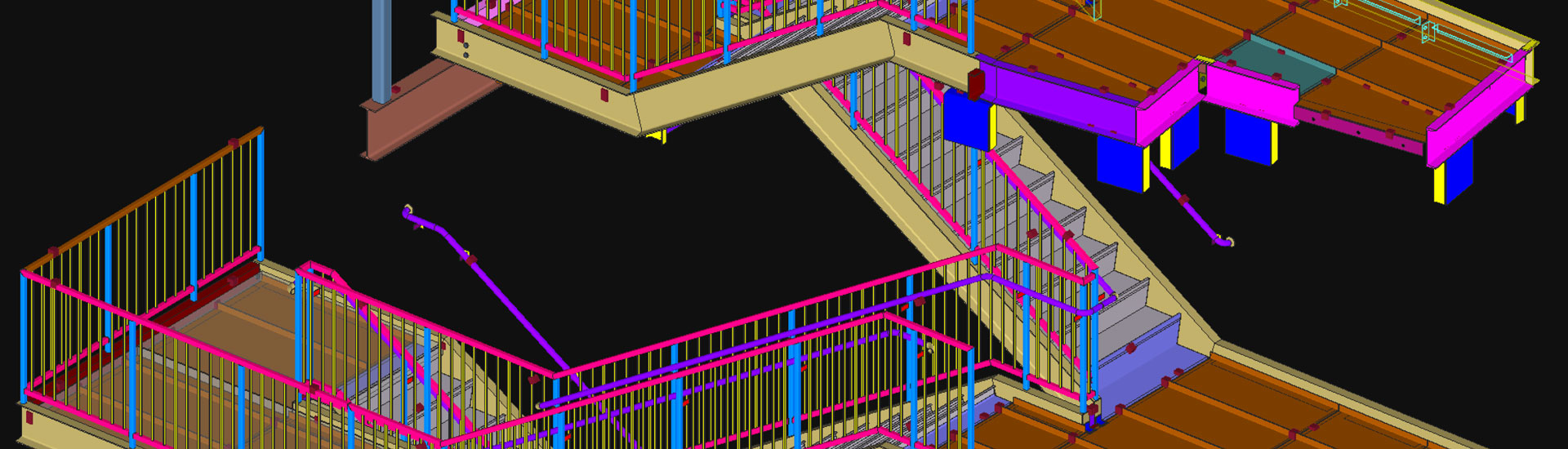

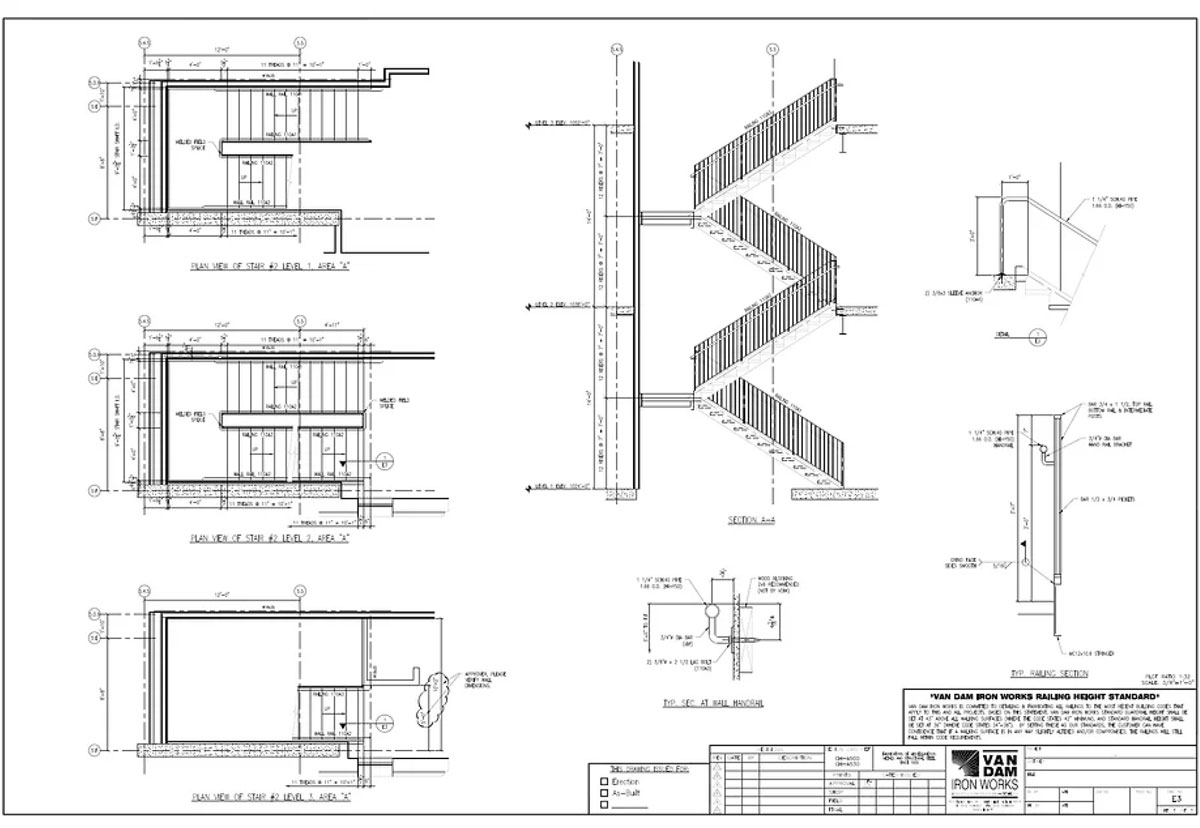

- Design / Detailing using SDS2

- Engineering Calcs and Stamps

- Project Management

- Complete Custom Fabrication

- Delivery

We use some of the newest technologies to increase our efficiency

Engineering, Design and Detailing

Van Dam Iron Works offers professional detailing using SDS2, including 3D modeling services and shop-ready CAD files for fabrication. We also provide professional engineering services for design calculations and sealed drawings.

Project Management

Our team is experienced, knowledgeable and committed to the success of your project. Professional project management is available for all projects, regardless of the size.

Our customer service is second to none.

Facility

Our shop was originally constructed in 1956, with additions in 1998 and 2019 bringing our total fabrication space to 49,500 SF, including a 3,000 SF dedicated paint shop. Overhead cranes ranging from 2 to 10 tons serve 100% of our facility

Equipment

Dragon A400 CNC

Tube and pipe plasma cutter

Tru-Weld Stud Welder

1” maximum stud diameter

NC Mandrel Pipe Bender

20’ stock with tooling for 1.25” and 1.5” schedule 40 pipe

AccuPress Press Brake

12’ bed with 250 ton capacity

Portable Plasma Cutters

At every fabricator’s work station

Welders

15+ MIG/TIG welders

PythonX Plate/Structural Robotic Plasma

40’ bed with 2” mild steel cutting capacity

Marvel Vertical Band Saws

18” manual and 21” CNC saws, both with mitering capabilities

Ocean Avenger Single Spindle Drill Line

40’ bed with 2” maximum hole diameter

AccuShear Plate Shear

10’ blade with 0.50” mild steel capacity

Iron Workers

Geka 110 with infeed conveyers, several other stand alone machines